5400 Tension Brakes Reduce Costs from Less Wear and Tear.

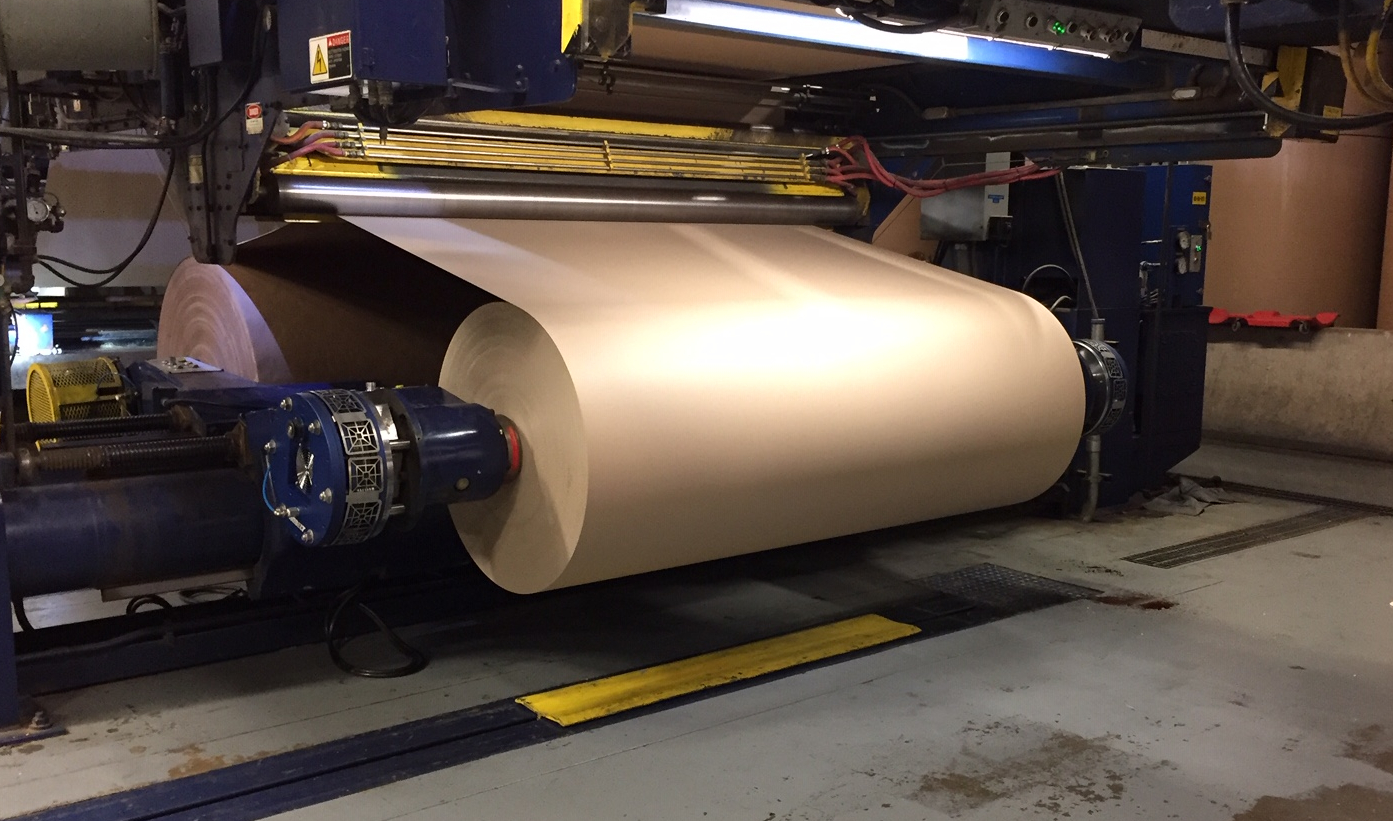

We are proud to share a recent customer testimonial after Harman Company successfully installed the new Kobelt 5400 series brakes at a Georgia Pacific corrugating plant in Texas.

“The performance of the Kobelt brake systems that you guys have installed here at Waxahachie has been outstanding. We have noticed significant changes with what we have installed thus far. As you know we have been running the first set for over a year now with little to no wear on pads or the brake system as a whole. The Kobelt brakes have reduced the cost of buying and replacing pads as well as rotors. I am not at liberty to discuss $ amounts but it has made an impact on inventory reduction & upkeep cost for routine maintenance across the board. I am looking forward to installing the last 3 sets of brakes to completely outfit my entire corrugator. I appreciate the efforts and customer service you guys have had through this transition and look forward to continued excellent service in the future.”

- Reliability Manager , Georgia Pacific - Waxahachie, TX

With virtually no pad wear after over a year of operating, Georgia Pacific is thrilled with the lengthy intervals between pad changes. When the time comes that the pads will need to be changed, it is also worth noting that this process is very quick and easy.

Equally important, the actuator sequence valve on the 5400 brake triples low end torque sensitivity which enables more accurate tension control over the entire roll (from 60” OD to a 6” core). Improved tension control translates to fewer web breaks which means increased productivity.

The 5400 brake can be used in may different applications, so don't hesitate to contact Kobelt or a Kobelt Partner for further information on the 5400 series or go to http://www.kobelt.com/products/disc-caliper-brakes/list/tension-brakes.